Production Capabilities

Since its inception, R&A Plastics has placed a strong emphasis on production, with a substantial portion of its investments dedicated to enhancing production capabilities. Our primary manufacturing method is plastic injection molding. In addition to injection molding, we offer several value-added processes, including insert molding, pad printing, mold making, and customized product assembly. All these processes are designed to support mass production.

| S.No | Machine description | Quantity |

|---|---|---|

| 1 | 110 Ton Boss Automatic Injection Moulding Machine | 1 |

| 2 | 110 Ton Electronica Automatic Injection Moulding Machine | 1 |

| 3 | 100 Ton YIZUMI Automatic Injection Moulding Machine | 1 |

| 4 | 150 Ton Electronica Automatic Injection Moulding Machine | 1 |

| 5 | 210 Ton Electronica Automatic Injection Moulding Machine | 1 |

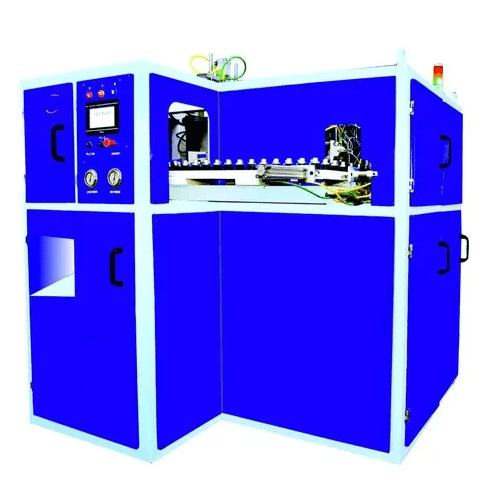

| 6 | 3 Cavity Magnum Semi Automatic PET Blow Moulding Machine | 1 |

| 7 | 2 Cavity Magnum Automatic PET Blow Moulding Machine | 1 |